Established to meet this potential, hotels go through a series of preparation phases before they become operational. Market research, establishment location selection, preparation of architectural plans and projects, actual construction works, legal proceedings, personnel recruitment, etc...

Systematic Arrangement Plan in Hotel Kitchens...

Implementation of Systematic Workplace Arrangement Plan (SIDP) Model in Hotel Kitchens

Murat DOĞDUBAY,

İkrar KARAN...

Summary

A large number of hotel businesses are established every year in our country. While the planning and layout of the sections of these hotel businesses constitute an important problem, one of the most complex areas to plan is the kitchens. Hotel kitchens represent systematic food production areas that consist of more than one section in terms of technical structure and equipment. In this study; The structure of large hotel kitchens, their departments, layout problems, the workflow in kitchens and the relationship of kitchen plan with work flow are discussed.

kitchen planning; It has been examined within the scope of facility planning and the subject has been tried to be explained within the scope of workplace placement scheme. The proposal to create the kitchen plan according to the Systematic Workplace Arrangement Plan (SIDP) model, which is one of the workplace placement methods, constitutes the main purpose of this study. In this direction; A theoretical research was conducted using the document review method, one of the qualitative research techniques. As a result of the research; It was determined that the qualitative and quantitative features needed during the planning of large hotel kitchens were determined and included in the planning.

LOGIN

In Turkey and in the world, the number of tourists participating in the tourism movement is increasing rapidly every year. In this direction, in parallel with the increase in tourism income, hotel businesses of various sizes are opened. In 2013, the number of five-star hotels in Turkey increased from 375 to 413 with a 10% increase compared to the previous year, and the number of 4-star hotels increased from 578 to 602 with a 4% increase.

In 2014, the number of five-star hotels increased from 413 to 529 with an increase of around 25% (TUIK, 2016; KTB, 2016). In addition, at the end of 2014 and in the rest of 2015, more than 152 four and five star hotels became operational with an increase of approximately 30% (Tourism Investment Magazine, 2016).

In 2016, it is expected that 124 more hotels will be opened and the number of 5-star hotels will exceed 563 (TÜROFED, 2016). In terms of numbers, it can be seen that the number of hotel businesses in Turkey is increasing rapidly every year. This means hosting thousands of people and meeting their food and drink needs.

Established to meet this potential, hotels go through a series of preparation phases before they become operational. Market research, establishment location selection, preparation of architectural plans and projects, actual construction works, legal proceedings, personnel recruitment, etc. It is possible to count many studies such as these among these preparations.

One of the most important preparatory works is the problem of the physical structure and layout of the hotel to be built. Kitchen planning is the most complex and costly part of this problem. Therefore, challenging tasks await the project team that carries out the hotel planning.

During the construction of the hotels, the requirements of the kitchen plan will be determined correctly during the installation phase and included in the planning, and many potential problems will be prevented (Budak, 2015). For this, the project phase of the kitchen plan is of great importance (Bayram, 2011). Establishing the right project team, determining all the needs by experts regarding a good preliminary study, dealing with the issue in a more systematic way will ensure the desired results from the investment made.

Kitchen Plan and Workflow in Hotel Businesses

In today's modern hotel businesses, it is seen that there are great changes compared to the past years. While some of these changes are realized in order to meet the demands and expectations of the customers in the best way, some of them are the products of the efforts of the enterprises to continue their activities by creating differences in the face of increasing competition (Budak, 2015).

Hotel businesses, which are one of the tourism businesses, are businesses that carry out their personnel, architecture, practices and relations with customers with certain rules and standards in order to meet the accommodation needs of the customers as well as other needs (Kozak et al. 2008). modern hotels; With its many facilities such as cafes, disco halls, entertainment centers, animation shows, laundry and dry cleaning facilities, parking lots, spa and thermal units, beauty salons, treatment centers, artistic activities, meeting place, it is rich in order to meet all kinds of needs and expectations of customers during their stay. offers opportunities (Türksoy, 1997; Aktaş, 2002).

These architectural designs, each of which is planned in detail, should be able to bring functional features as well as aesthetics to hotel businesses (Budak, 2015). Because the design or general architectural structure of a constructed facility does not have a chance to be changed much later (Birchfield, 2008). In the most general definition, the kitchen is the areas where food is stored for certain periods, prepared, cooked and consumed in certain quantity and quality (Sacır, 1991; Asımgil and Şahin, 2004; Sökmen, 2003; Gökdemir, 2009). There are many different kitchens and Kitchen Units in hotel businesses.

These; hot kitchen, cold kitchen, patisserie, butcher shop, vegetable preparation, breakfast preparation, as well as banquet kitchen, room service kitchen, snack kitchen, pool bar kitchen, beach bar kitchen and a la carte kitchens (Aktaş and Özdemir, 2007). ).

It is quite difficult to decide on the layout of the kitchen. For this, the area allocated to the kitchen and the flow order of the work to be produced should be well known. A layout type can be chosen for the general kitchen, as well as a layout type suitable for the workflow of each section.

This layout planning is the result of the collaboration of architects, professional industrial kitchen planners , engineers and kitchen chefs with years of experience. If the kitchens are to be grouped according to their physical layout; They can be grouped as Island Type, Corridor \ Parallel Type, Scattered Type, H type, L Type, U Type, I (Single Wall or Flat) Type, G Type, S Type and Rectangular Type kitchens (Budak, 2015). In hotel businesses, the kitchen is located in the production center.

The plan element greatly affects the use of money, time and energy during the activity (Mignanelli, 2004). The points to be considered in the preliminary study on kitchen planning are as follows:

amount of food to be produced, menu, quality of the establishment (number of stars), customer profile, budget allocated, service method, environmental factors, personnel, equipment to be used, competition conditions, storage, workflow, hygiene, purchasing and storage conditions, official obligations, miscellaneous operational issues, ergonomics, maintenance, location of the kitchen, allocated space, land structure, operating concept, bed capacity and so on (NFSMI, 2002; Türkan, 2003; Aktaş and Özdemir, 2007; Sarıışık et al., 2010; Öztaş and Uçan, 2002 ; Aktaş, 2011; Campbell and Foskett, 2012; Budak 2015).

Thanks to a good kitchen plan, healthy communication between kitchen departments is ensured, occupational health and safety and food safety are protected, Efficiency in Kitchen Management increases, the quality of the finished product increases and a good service is provided to customers (Campbell & Foskett, 2012). A good kitchen plan should have the following features: functionality, life and work safety, hygiene, prevention of waste of space, time, labor, energy and materials, cost reduction, flexibility, material, workforce flow and facilitating control, the most efficient use of space, etc. (Koçak, 2009; Aktaş and Özdemir, 2007). On the other hand, the main mistakes to be avoided while planning the kitchen can be listed as follows:

The kitchen area is small compared to the work

Lack of special working areas belonging to parts of the kitchen

Absence of partitions

narrow corridors

Unplanned placement and inappropriateness of private workspaces

Insufficient ventilation system

The kitchen is far from the halls where the meals are served.

Incorrect installation and/or insufficient equipment

Lack of adequate cold rooms or freezer rooms

The heights between the cooktops and cooktops and the work benches are not in accordance with the standards.

Absence or insufficient hot-cold water sinks in required areas

Lack of hand-washing sinks that work without touching

Lack of special garbage storage rooms

Incorrect or insufficient lighting

No WCs, showers or cloakrooms for staff

Lack of safety equipment, etc. (Türkan, 2003; Bayram, 2011; Budak, 2015).

Workflow Process in Hotel Kitchens

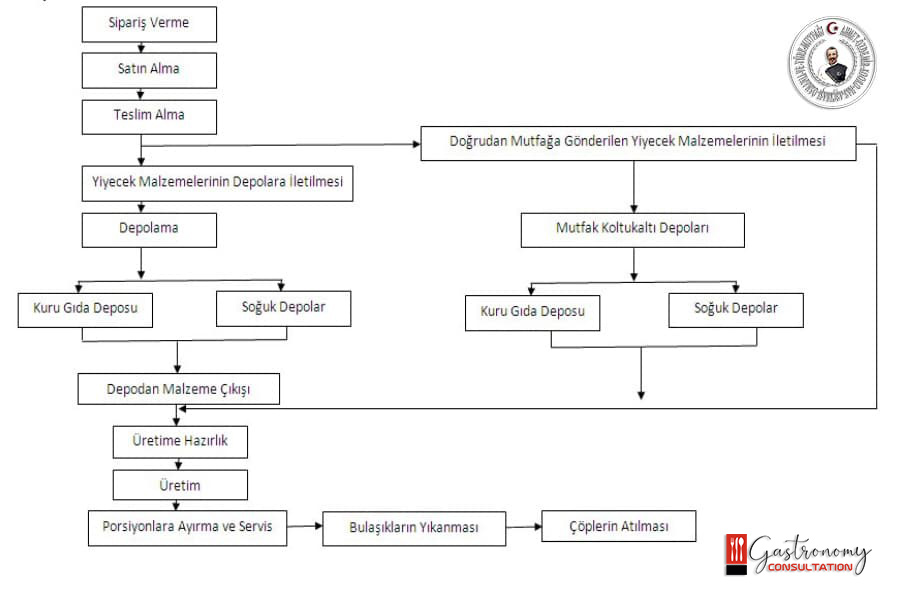

Figure 1. Workflow Process in Hotel Kitchens (Aktaş and Özdemir, 2007)

The kitchens, which operate in parallel with the star rating of the hotels, constitute important food production centers. Kitchen buildings need to be arranged in such a way as to provide a continuous flow from the receipt and storage of foodstuffs to their preparation and transformation into a final product (Mignanelli, 2004). According to Ak (2009), it is of great importance that the flow within the workstations be symmetrical, simultaneous, natural, rhythmic and familiar. When starting from these points, the workflow; It is possible to define it as the path followed during the production of materials, parts and semi-products (Özcan, 2005).

In order to carry out the work flow study, it is necessary to obtain information about the works first. For this purpose, the beginning and end points of the work are determined correctly by making job analyzes (Benligiray, 2005). Workflow in kitchens; It refers to the sum of certain processes during food production, that is, from which point the food production will start and at which point it will end, and which activity will be carried out at which station between these points. As a result of the correctly planned work flow in the kitchens, employees can have the opportunity to work more efficiently and with higher motivation with less risk (Budak, 2015). A very complex structure should not be preferred in the kitchen layout and it should be preferred that the structure be simple, easy and accessible (Çalışkan, 2006).

There are differences between working in a hotel kitchen and working in a traditional kitchen. In large central kitchens, large quantities of raw materials are purchased and large quantities of food are produced. This consists of a series of repetitive activities (NFSMI, 2002). In Figure 1 below, the systematically repeated workflow during production in hotel kitchens is shown schematically.

Placement Layout in Hotel Kitchens Workplace layout arrangement (facility layout, facility design, factory placement, etc.); It is the optimum planning of industrial sections with their employees, production machinery and equipment, material handling systems and vehicles, and all other auxiliary services (Özcan, 2005). In other words, with workplace arrangement, the workflow of the product from the raw material to the processed product is facilitated (Erkut and Baskak, 2003). A well-organized workplace increases productivity and reduces overall costs (Sha and Chen, 2001).

The fact that the areas are not well planned and placed in food and beverage production enterprises adversely affect production, service costs and efficiency. In addition, this situation causes negative behaviors, frictions and not working of the existing equipment effectively (Budak, 2015). Especially in kitchens, an incompatible equipment layout can mean potential accidents and occupational diseases. These negativities affect the employee's continuation, productivity, and psycho-social status (Çekal, 2013), and also lead to an increase in waste.

The location of the kitchen, lighting, ventilation, heating, flooring, height, fire and installation equipment, walls, area, installation spaces, doors and windows, elevators, parts of the kitchen, etc. Qualitative and quantitative features of how physical properties such as such should be should be determined with a meticulous study and a 'Kitchen Plan Checklist' should be created (Budak, 2015). As a result of determining these standards in detail according to the needs, it will be easier to obtain an effective kitchen plan. According to Inglay and Dhalla (2010), each workplace has its own assumptions, constraints and limitations.

In the layout approach, the problems cannot be applied to the model, the models have to be applied according to the problems. Hotel kitchens also have a system within themselves and their physical planning should be systematized. The Systematic Layout Planning technique, developed by Richard Muther, is a method that allows many qualitative factors to be taken into account in the settlement (Şahin and Türkbey, 2010).

Its success in solving numerous problems in practice causes operators to adopt this system. This planning approach; production, transportation, storage, determination of the location of workstations according to flow patterns, entrances and exits, etc. applicable to any problem.

Kitchen layout planning needs to be carried out by a project team consisting of the business owner and construction professionals (architect, engineer, kitchen manager, equipment salesman, etc.). It would be very beneficial for industrial engineers to collaborate with architects and cooks while planning the kitchen (Budak, 2015). The combination to be created for the project team varies according to the size and complexity of the facility (Birchfield, 2008).

Kitchen planners have some basic standards at hand when drawing up plans. While some of these standards are developed as a result of experience, others are obtained as a result of careful studies (Rudard and Kapple, 1975).

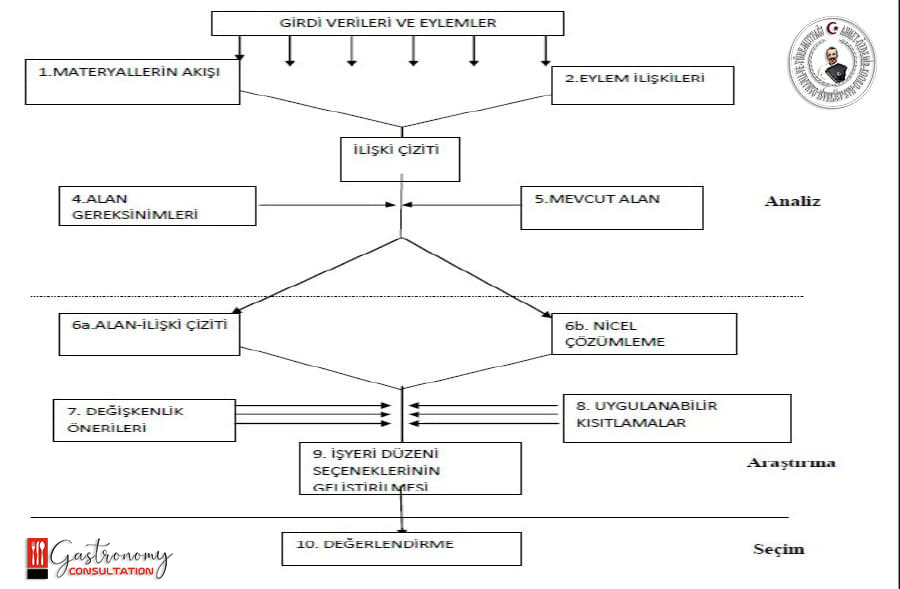

Figure 2. Systematic Workplace Arrangement Planning Model (Heng, 2003).

Systematic Workplace Arrangement Planning Model

The criterion aimed at determining the factory layout is not always the minimization of the material handling amount or cost. In some cases, factors that cannot be expressed numerically are taken into account in the preparation of the layout plan (Sha and Chen, 2001). In this direction, there are many models and methods proposed for the workplace arrangement problem. One of them is the Systematic Workplace Arrangement Plan (SIDP). Systematic Workplace Arrangement Planning (SIDP) is an approach that considers the workplace organization problem as a planning problem (Ak, 2009).

In this method, by following a systematic process with some steps followed, the areas with intense relations between them are placed side by side or close, so that the travel of material and labor is maximized (relationship diagrams are created) and planning can be made by calculating the number of employees. At the project stage, a study like SIDP is aimed at drawing the kitchen plan and minimizing it during operation (Heng, 2003).

According to the SIDP model, the sections to be placed are determined separately (stock section, areas for work benches, areas for sinks, etc.). Because when an architect creates the kitchen plan, he generally thinks of the drawing spatially. It does not prioritize equipment and workflow. However, if we have information about such matters, that is, what the expectations of the cook who will work in the kitchen are known, the kitchen plan can be created more appropriately.

For the SIDP, the flow analysis is combined with an action analysis to prepare the relationship diagram after the appropriate information is gathered. The parts related to the area are also combined with a diagram and the area relationship diagram is established. Then, various workplace plans are made, taking into account the applicable restrictions. SIDP begins after the problem has been formulated. The first five steps of planning constitute the analysis of the problem, the steps from six to nine, the presentation of various workplace layouts, that is, the research phase for the planning process (Erkut & Baskak, 2003).

Systematic Workplace Arrangement Planning

The Applicability of the Model in Kitchens The efforts to gain competitive advantage in hotel businesses are not limited to service diversification, but continue in the form of hotels with different architectural designs. It is an important issue to plan the hotel facilities built in accordance with the purpose of the activities aimed to be continued. It is a known fact that the establishment of hotel facilities creates high costs. The problem of layout of a complex facility encompasses many complex problems. As a result of the work carried out by the professionals involved in the construction of the hotel; these complex problems are overcome.

After the completion of the construction works of the hotel, the mistakes made in the planning can be observed much better with the commencement of its activities. In this case, various arrangements are made to eliminate planning errors later on. These arrangements can take place in the form of demolition and rebuilding of some parts, or they can be made in the form of partial arrangements. However, in some cases, it is almost impossible to make these changes afterwards. The planning should be prepared very carefully while still in the construction phase so that the investment costs do not increase further, the activities are not disrupted and the service is offered at a level close to the determined quality standards.

Kitchen management, Restaurant management, Kitchen planning, Kitchen organization, Types of cuisine, Culinary education, Menu planning, Menu management,workplace layout; a facility, its equipment, auxiliary areas, workstations, warehouses, production-related activities, etc. means to be arranged in such a way that optimum results are obtained. A well organized facility; It will prevent loss of labor, time and value, reduce operating costs, increase employee motivation, enable hygiene and effective communication, facilitate management and control, and furthermore, prevent disruption of production in kitchen management .

The kitchen department has a systematic feature throughout its food production activities, as in other production facilities. Therefore, systematically addressing the work flow in the kitchens and planning the space, equipment and the work flow relationship in a systematic way during the planning of the space where these activities are carried out will provide much more effective kitchen planning. It is possible to liken the kitchens of hotel businesses to a workshop due to its structure, large number of employees, equipment, and production-based activities.

Therefore, it may be appropriate for industrial engineers to take part in the creation of the kitchen plan through the "Systematic Workplace Arrangement Plan", which is used in the planning of many workshop and factory buildings, in order to develop more suitable kitchen plan projects. The Systematic Workplace Arrangement Plan model, which is used by industrial engineers in the planning of many production facilities and developed by Richard Muther in the 1960s, can also ensure that the qualitative dimensions of the planning can be brought to the fore.

In today's construction and interior design works, there are package programs that can be computer-aided drawing. These programs can offer a large number of planning examples. These programs offer examples of plans that mainly contain quantitative features. However, especially in the physical planning of the kitchen of a large hotel business, qualitative factors should also be taken into account. The common practice in kitchen planning in the hotel industry is to give the project to industrial kitchen companies (Birchfield, 2008).

Some of the companies that make professional industrial kitchen planning in this regard in Turkey; İnkom, İnoksan, Chrome Kitchen, Chrome Luxury, Öztiryakiler, Gürçelik, Noyilmaz, Crystal etc. is Autocad, KitchenDraw, Arcon Open Vray etc. are computer programs that are widely used in these companies.

During the preparation of the kitchen plan, the creation of a kitchen plan project execution team and the determination of a project team consisting of an architect, kitchen manager, food and beverage manager, hotel general manager, hotel owner, industrial engineer, industrial kitchen equipment sales representative, and civil engineer. It will be useful in terms of carrying out the planning in the most correct way. It would be more appropriate for the kitchen chef, industrial engineer and architect to be appointed as chief executives in this project team.

This will prevent the confusion that may arise due to the large number of people among the kitchen plan project coordinators. In addition, the creation of a checklist by the project team, such as the Kitchen Plan Checklist, which was created as a result of this study and presented as an example in Table 1 on what the necessary qualitative and quantitative features should be for the kitchen plan, will prevent some elements from being overlooked. This preliminary preparation will ensure that the Systematic Workplace Arrangement Planning is carried out more regularly and healthily.

*Table 1. Kitchen Plan Checklist (Aktaş and Özdemir, 2007; Aktaş, 2001; Aktaş, 2002; Aktaş, 2011; Bulduk, 2013; Denizer, 2005; Doğu,

|

Topic title

|

Checklist Topics

|

Yes

|

No

|

reasons

|

to be taken

Measures

|

|

KITCHEN EQUIPMENT

|

Is sitting work bench height 65 cm on average?

|

|

|

|

|

|

Is the standing bench height 85 cm on average?

|

|

|

|

|

|

Are the dimensions of the equipment suitable for the employees and the working environment?

|

|

|

|

|

|

Is the distance between the work bench and the cooker at least 90-120 cm?

|

|

|

|

|

|

Is the distance between two ranges or ovens and ranges 90 - 120 cm?

|

|

|

|

|

|

Are the distances of the vehicles from the wall 0 or 45 - 60 cm?

|

|

|

|

|

|

Is the distance in front of large equipment 90 - 120 cm?

|

|

|

|

|

|

Do the shelves have a maximum height of 180 cm from the ground?

|

|

|

|

|

|

Is the height between two shelves at least 50 cm?

|

|

|

|

|

|

Are tools and materials placed close to the area where they will be used?

|

|

|

|

|

|

Is the dough rolling counter average 120 cm?

|

|

|

|

|

|

Is the opposing counter width at least 150 cm?

|

|

|

|

|

|

Is the width of the additional person bench at least 90 cm?

|

|

|

|

|

|

Is the width of the service counters 60 cm on average?

|

|

|

|

|

|

Is the average height of the service counters 85 cm?

|

|

|

|

|

|

Are tools and equipment placed in line with the workflow?

|

|

|

|

|

|

Is the equipment securely fixed to the ground?

|

|

|

|

|

|

Are the pipes, cables, coming to the equipment protected with protective shields?

|

|

|

|

|

|

Has the right equipment been selected?

|

|

|

|

|

|

Is unnecessary equipment used?

|

|

|

|

|

|

VENTILATION

|

Is the ventilation system suitable?

|

|

|

|

|

|

Do the temperature rates average 18ºC in summer and 22ºC in winter?

|

|

|

|

|

|

Is each section heated or cooled as needed?

|

|

|

|

|

|

Is the kitchen humidity 60% maximum?

|

|

|

|

|

|

Are the chimneys pulling properly?

|

|

|

|

|

|

Are there enough/capacity-appropriate number and suitable quality hoods?

|

|

|

|

|

|

Can the air in the environment change periodically 20-30 times per hour?

|

|

|

|

|

|

Is the height between the hoods and the floor 190-210 cm?

|

|

|

|

|

|

Is the protrusion of the hoods 20-25 cm larger on all sides compared to the galley area?

|

|

|

|

|

|

LIGHTING

|

Is natural lighting used?

|

|

|

|

|

|

Is the lighting 200 lux in work areas?

|

|

|

|

|

|

Is the lighting 300-500 lux in places like stoves and countertops?

|

|

|

|

|

|

Is the lighting at least 100 lux in other areas?

|

|

|

|

|

|

Is white light used for lighting?

|

|

|

|

|

|

Is frosted glass used for lighting?

|

|

|

|

|

|

Is the total surface of the window at least ¼ of the room floor?

|

|

|

|

|

|

Is the level of illumination equal in all parts of the working environment?

|

|

|

|

|

|

Is uniform lighting provided?

|

|

|

|

|

|

Is the light source not flickering?

|

|

|

|

|

|

Doesn't the lighting cause glare?

|

|

|

|

|

|

NOISE

|

Are noise-absorbing materials used in the construction of the walls?

|

|

|

|

|

|

Is the noise of the working environment below 85 dB(A) on average?

|

|

|

|

|

|

Are noisy equipment away from the working environment?

|

|

|

|

|

|

WALLS

|

Are the tiles at least 2 meters above the ground?

|

|

|

|

|

|

Is the wall painted in a light color?

|

|

|

|

|

|

Is there a protector on the kitchen walls?

|

|

|

|

|

|

Is the wall surface flat?

|

|

|

|

|

|

the preparation and cooking equipment 120 cm on average?

|

|

|

|

|

|

Is it covered with a metal strip along the wall corners and the line of wheeled vehicles?

|

|

|

|

|

|

CEILING

|

Is the ceiling height from the ground 4-6 meters?

|

|

|

|

|

|

Does the ceiling color match the walls?

|

|

|

|

|

|

Is the ceiling surface also a porous structure that does not contain dirt and is not affected by humidity?

|

|

|

|

|

|

Are the installations in the ceiling hidden?

|

|

|

|

|

|

GROUND

|

Is the floor made of waterproof, durable, non-slip material?

|

|

|

|

|

|

Is the slope of the ground suitable?

|

|

|

|

|

|

Are there any cracks or cracks on the floor?

|

|

|

|

|

|

Are the slopes suitable for ergonomic conditions (minimum 0º, maximum 20º, most suitable 15º)?

|

|

|

|

|

|

Is the pattern used on the floor complex?

|

|

|

|

|

|

Is the floor color light and in harmony with neighboring surfaces?

|

|

|

|

|

|

Does the size and structure of the material used require more joints?

|

|

|

|

|

|

Are there enough grate water drains in the required areas?

|

|

|

|

|

|

Are the floors of garbage rooms and warehouses made of suitable materials?

|

|

|

|

|

|

AREA

|

Salute, 5% of the total area?

|

|

|

|

|

|

Is the preparation area approximately 10% of the total area?

|

|

|

|

|

|

Are the dry and cold stores each approximately 10% of the total area?

|

|

|

|

|

|

Is the daily warehouse approximately 5% of the total area?

|

|

|

|

|

|

Is the cooking area approximately 15% of the total area?

|

|

|

|

|

|

Is the staff room approximately 10% of the total area?

|

|

|

|

|

|

Is the executive room about 5% of the total area?

|

|

|

|

|

|

Is the kitchen area sufficient according to the capacity?

|

|

|

|

|

|

Are there dead spaces (doors, partitions, corridors) that require unnecessary walking?

|

|

|

|

|

|

Is the area layout suitable for change?

|

|

|

|

|

|

ELECTRICITY, WATER AND OTHER INSTALLATIONS

|

Is the electrical installation grounded and waterproof?

|

|

|

|

|

|

Is there a 24-hour hot water system?

|

|

|

|

|

|

Are all installations in compliance with TSE?

|

|

|

|

|

|

Is the capacity of all installations appropriate for the nature of the service?

|

|

|

|

|

|

No external power cable or is it insulated?

|

|

|

|

|

|

In the event of a water cut, is there a water tank and hydrophore that will meet the 2-day need?

|

|

|

|

|

|

Has the water used passed through a 0.5 micron filter and reduced to 5 Fr degrees of hardness?

|

|

|

|

|

|

Is the waste water system arranged in accordance with the regulation?

|

|

|

|

|

|

Can oily water be treated where it is produced?

|

|

|

|

|

|

SECURITY

|

Is the natural gas installation safe?

|

|

|

|

|

|

Are sharp corners avoided?

|

|

|

|

|

|

Is there a manually operated main shut-off valve for gas?

|

|

|

|

|

|

Is there a main button in the kitchen that can cut off all power and lighting electricity?

|

|

|

|

|

|

Is an alarm system installed at every point?

|

|

|

|

|

|

Is there a fire exit door?

|

|

|

|

|

|

WASTE

|

Can garbage be collected daily?

|

|

|

|

|

|

Is the litter chamber refrigerated?

|

|

|

|

|

|

the temperature of the garbage rooms +10 o C on average?

|

|

|

|

|

|

Is the aisle for receiving food and garbage collection separate from each other?

|

|

|

|

|

|

Are the garbage rooms in an area away from the kitchen area?

|

|

|

|

|

|

Are suitable rooms planned for the separation and storage of garbage according to its type?

|

|

|

|

|

|

Are there faucets running hot-cold water in the garbage storage section?

|

|

|

|

|

|

Is there a suitable area for garbage trucks to approach the garbage rooms comfortably?

|

|

|

|

|

|

GENERAL KITCHEN

LAYOUT

|

Is the corridor width at least 150 cm?

|

|

|

|

|

|

Is the width of the sinks 60 - 90 cm?

|

|

|

|

|

|

Is the correct flow provided from purchase to service? (Purchase, storage, preparation, cooking, service)

|

|

|

|

|

|

Are there enough handwashing sinks?

|

|

|

|

|

|

Are the kitchen sections properly planned?

|

|

|

|

|

|

Are there partitions between the kitchens?

|

|

|

|

|

|

Is the slope of the stairs between 20 - 50 degrees?

|

|

|

|

|

|

Are the stairs suitable for ergonomic conditions (slope at least 20º, maximum 50º, most suitable 30º-45º)?

|

|

|

|

|

|

The steps are suitable for ergonomic conditions.

(height at least 13, maximum 20 cm, optimal 16-18 cm, depth 26.5-30.5 cm, width at least 51 cm)?

|

|

|

|

|

|

Is the clearance between the cabinets at least 90 cm?

|

|

|

|

|

|

Are there untouched washbasins where necessary?

|

|

|

|

|

|

Are there large enough waste water expenses?

|

|

|

|

|

|

Are there hygiene mats at kitchen entrances?

|

|

|

|

|

|

Are there shoe covers, bonnets and apron cabinets at the kitchen entrances?

|

|

|

|

|

|

Are there handwashing sinks that work untouched at kitchen entrances?

|

|

|

|

|

|

Do kitchen doors open and close by themselves?

|

|

|

|

|

|

Is sufficient space reserved for the approach and maneuvering of vehicles in the pick-up area?

|

|

|

|

|

|

Is the loading and unloading ramp in the pick-up area between 90-110 cm?

|

|

|

|

|

|

Is there an office for purchasing officers?

|

|

|

|

|

|

Is there enough stowage space in the dishwashers?

|

|

|

|

|

|

Is the area where the dishes are washed and the area where they are stacked separate from each other?

|

|

|

|

|

|

Is the dishwashing room planned to be far from the production areas and close to the service areas?

|

|

|

|

|

|

Is the ventilation of the dishwashers appropriate?

|

|

|

|

|

|

Are there washing, rinsing and sterilization chambers in the boiler washing section?

|

|

|

|

|

|

Are the toilets at least 8 meters from the kitchen?

|

|

|

|

|

|

Are the food, garbage and service elevators separate?

|

|

|

|

|

|

If the use of elevators is necessary, are the elevators large enough?

|

|

|

|

|

*1994; Gokdemir, 2009; Koçak, 2009; Kolak, 2004; Sökmen, 2005; Turkan, 2003; Tumer, 2008; Caliskan, 2006; Turksoy, 1997).

CONCLUSION

In this study, the qualitative and quantitative standards required for hotel kitchens in general and especially for the kitchens of large hotel businesses, the effect of the kitchen plan on the workflow, how the most effective kitchen planning should be, and whether it is possible to carry out the kitchen planning activity according to the Systematic Workplace Arrangement Plan model. Subjects such as these are examined based on the sources in the literature. Each of the physical sections of the kitchen and the features of these sections (ventilation, heating-cooling, waste expenditures, lighting, cold cabinets, Kitchen Types and kitchen sections, etc.) require much more detailed technical knowledge.

Therefore, although it is not possible to include all the features of these subjects in a single study, it also necessitates specialist knowledge. That's why; While planning a hotel kitchen, it is necessary to reach more alternatives and take into account the latest technological developments by making use of the opinions of the engineers, architects, kitchen chefs and other experts in the project team.

RESOURCES

Ak, R. (2009). Analysis of Workplace Regulation Algorithms and a Factory Application. Master Thesis. Istanbul Technical University, Institute of Science, Department of Industrial Engineering, Department of Industrial Engineering, Istanbul.

Aktas, A. (2001). Food and Beverage Management. (2nd Edition). Livane Printing House, Antalya.

Aktas, A. (2002). Tourism Management and Management. (2nd Edition). Azim Printing House, Antalya.

Aktas, A. (2011). Food and Beverage Management in Hospitality Service Businesses (3rd Updated Edition). Detail Publishing, Ankara.

AYDIN GASTRONOMY, 1 (1):9-23, 2017

Murat DOĞDUBAY, İkrar KARAN

Aktaş, A. and Özdemir, B. (2007). Kitchen Management in Hotel Businesses. (2nd Edition): Detay Publishing, Ankara.

Asımgil, S. and Şahin, M. (2004). Culinary Culture. (1st Edition). Timaş Publications, Istanbul.

Bayram, F. (2011). Knowledge, Attitudes and Behaviors of Kitchen Staff Working in Hotel Kitchens on Food Safety Master Thesis. Gazi University, Institute of Educational Sciences, Department of Family Economy and Nutrition Education, Ankara.

Benligiray, S. (2005). Office management. (Extended 1. Just as Edition). Eskişehir: TC Anadolu University Open Education Publications No: 856.

Birchfield, John C. (2008). Design and Layout of Food Service Facilities (3rd Edition). Hoboken, NJ, John Wiley & Sons, USA.

Budak, I. (2015). A Systematic Process for Hotel Management Kitchen Planning, Balıkesir University, Institute of Social Sciences, Tourism and Hotel Management Program Master's Thesis, Balıkesir.

We found, S. (2013). Food Technology. (7th Edition). Detail Publishing, Ankara.

Campbell, J. and Foskett D. (2012). Practical Cookery For The Level 2 VRQ. (12th Edition). Hodder Education. UK., London.

Caliskan, S. (2006). Investigation of the Conformity of Kitchen Planning and Tools Used in Some Enterprises Producing Mass Meal in Mersin and Adana Provinces According to Standards. Master Thesis. Cukurova University, Institute of Science and Technology, Department of Food Engineering, Adana.

Implementation of Systematic Workplace Arrangement Plan (SIDP) Model in Hotel Kitchens

Cekal, N. (2013). Factors to be Considered in Kitchen Design in Food and Beverage Businesses . e-Journal of New World Sciences Academy, 8(1): 62-66

Denizer, D. (2005). Food and Beverage Management. (1st Edition). Detail Publishing, Ankara.

East, O. (1994). Hotels (3rd Edition). Birsen Publishing House, Istanbul.

Erkut, H. and Baskak, M. (2003). Facility Design from Strategy to Practice. (1st Edition). İrfan Publishing, Istanbul.

Gokdemir, A. (2009). Kitchen Services Management. (Sökmen Alptekin, Ed.) Detay Publishing, 3rd Edition, Ankara.

Heng, Huang. MS (2003). Facility Layout Using Layout Modules. Presented in Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy in the Graduate School of The Ohio State University, Ohio, USA.

Inglay, SR and Dhalla, SR (2010). Application of Systematic Layout Planning in Hypermarkets. Proceedings of the 2010 International Conference on Industrial Engineering and Operations Management. Dhaka, Bangladesh. P: 185-189.

Koçak, N. (2009). Food and Beverage Services Management. (4th Revised Edition). Detail Publishing, Ankara.

Kolak, T. (2004). Hotel Technology. (1st Edition). Dimension Books, Istanbul.

Kozak, MA Çakıcı, C. Azaltun, M. Sökmen, A. and Sarıışık, M. and Çetinsöz CB (2008). Hotel management. (Ed. Kozak, N.).

Detail Publishing, Ankara.

KTB (2016). Tourism Certified Facilities. TR Ministry of Culture and Tourism, General Directorate of Investments and Enterprises. http://www.ktbyatirimisletmeler.gov.tr/TR,9860/turizm-belgeli-tesisler.html (ET: 21.07.2016).

Mignanelli, A. (2004). Safe Information For The Safe Design Of Commercial Kitchens. WorkCover Corporation, South Australia:

NFSMI (2002). A Guide to Centralized Food Service Systems. National Food Service Management Institute, United States.

Ozcan, E. (2005). Facility Planning Techniques and Application in Furniture Industry (Mades Example). Master Thesis. Zonguldak Karaelmas University, Institute of Science and Technology, Department of Forestry Engineering, Bartın.

Öztaş, K. and Uçan, H. (2002). Kitchen Services in the Tourism Sector. Nobel Publication Distribution, Ankara.

Rudard, JA and Kapple, WH (1975). Kitchen Planning Principles: Equipment, Appliances. Small Homes Council - University of Illinois Urbana-Champaign.

Sacir, FH (1991). Food Preparation and Cooking Techniques 2. (2nd Edition). Ministry of National Education Publications Textbook Series, Gazi University Technical Education Faculty Printing House, Ankara.

Sarıışık, M. Sergeant, S. and Karamustafa, K. (2010). Professional Restaurant Management: Principles, Practices and Case Studies. (1st Edition). Detail Publishing, Ankara.

Sha, DY and Chen, CW (2001). A New Approach to the Multiple Objective Facility Layout Problem. Integrated Manufacturing Systems. 12\1: 59-66.

Sökmen, A. (2003). Food and Beverage Management in the Hospitality Industry. Detail Publishing, Ankara.

Sökmen, A. (2005). Food and Beverage Services Management and Management. (Extended 2nd Edition). Detail Publishing, Ankara.

Şahin, R. and Türkbey, O. (2010). A New Hybrid Heuristic Algorithm for the Multi-Purpose Facility Layout Problem. Journal of Gazi University Faculty of Engineering and Architecture. Volume 25, No. 1, 119-130.

TUIK (2016). Turkish Statistical Institute. http://www.tuik.gov.tr/UstMenu.do? method=baselist (ET: 15.07.2016).

Tumer, H. (2008). A Study on the Analysis of the Kitchen Plan and the Effects of the Kitchen Plan on the Workflow in Institutions Providing Mass Nutrition Service. Master Thesis. Hacettepe University, Institute of Health Sciences, Mass Nutrition Systems Program, Ankara.

Turkan, C. (2003). Kitchen Technology. UBF Food Solutions, Istanbul.

Turksoy, A. (1997). Food and Beverage Services Management. (1st Edition). Turhan Bookstore, Ankara.

TUROFED (2016). Turkish Hoteliers Federation. http://www.turofed.org.tr/turizm-raporu.html (ET: 10.08.2016).

As Has Chef Ahmet Özdemir, I see the source:

Mr. Murat DOĞDUBAY, I sincerely thank İkrar KARAN for his academic studies titled "Implementation of the Systematic Workplace Arrangement Plan (SIDP) Model in Hotel Kitchens" and wish him success in his professional life . It will definitely be considered as an example by those who need it in professional kitchens, related research and in the world of gastronomy.